Today, we cannot imagine life without USB flash drives and it seems they’ve been with us forever. They are used by everyone, everywhere, from home use to work and educational use, from students to corporation executives. Also, they have become one of the most used and efficient promotional tools by companies or other organisations, to endorse their businesses in every market segment.

When an organisation is considering purchasing promotional USB flash drives, usually contact and deal with a local supplier. Dealing directly with the Far East USB sticks manufacturers, you can get big discounts, but they will most likely skip some manufacturing steps, which we’ll talk about a little later, leading to products of lesser quality. In addition, they will expect upfront payment, before the production even commences, and if things go wrong, well, you have to deal with them on your own.

We could tell you how our business, is the best, the most awesome, the most professional branded USB products supplier and how we sell to everyone everywhere, but it’s better to find this out yourself. What we can assure you is that, unlike many other suppliers, UBS Company will closely supervise the the manufacturing process of your promotional items and will make sure it is fully audited and of the highest quality.

When you look for a supplier, take some aspects into consideration. The price of their products is important, of course, but it should not be the only criteria. The cheapest deal is not always the best deal, as we are sure you this from your own experience. The promotional USB sticks should reflect your business standard and if they break down after a short while after they were received by your customers, think how it will reflect on your brand. It’s a reputational risk and a major inconvenience to get these gifts replaced. So, when you start looking for your supplier, make sure you can contact one of their representatives, by phone is better than by e-mail. Also, contact their previous clients, to see other companies’ experience with them, and check if they use new USB flash drives, not refurbished ones. Another aspect to check is the supplier’s business premises. You don’t want to deal with individuals that cannot give any support in case some things go wrong. Simply use Google Earth to see where their headquarters is. And one last aspect, don’t pay for anything until your products are ready to be delivered.

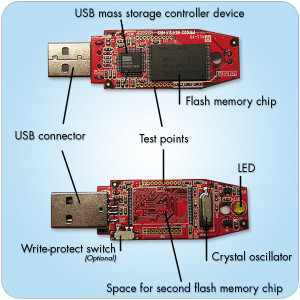

After you have chosen your supplier, there are also some manufacturing facts you should know about. This process is not a simple one, but rather a challenging one. First thing, and there is no secret about it, the majority of the promotional USB products are made in Taiwan or China. The flash drives are built from three major components:

- The flash memory chip that holds the actual memory capacity of the USB drive, with sizes from 64MB to 256GB

- The PCBA board, the component that houses the chip, other electronics and the USB connector

- The body of the flash drive, or the casing, that holds and protects the electronic part of the products.

Your supplier will be responsible for ordering these three major components and the factory for purchasing and assembling them. Now, usually, the manufacturing process is as follows:

The factory will purchase the flash memory chips from different companies like Intel, Hynix, Micron, Samsung or other brands

The flash memory chips are QA tested before they are attached to the PCBA board

If the preload service was opted, all data will be transferred and other modifications will be made at this stage

The unit is QA tested again and a screen shot of the data and its structure will be sent to the client for an approval

The factory will purchase the USB’s casing.

The factory will make the modifications on the USB’s body, like screen printing, engraving or embossing. Again, photos of the product will be sent to the client for approval.

The PCBA is inserted into the casing

Assembled units are fully QA tested again

Accessories are added at this point

The USB flash drives are packed into custom made packages or simple bubble bags, depending on your order

The products are shipped to your supplier, after they pass custom controls.

By now, 7 to 14 days have passed, and when the products arrive to your supplier, the USB flash drives should be QA tested again, with your suppliers’ own tests, before they are sent to you.